In today’s fast-paced industrial landscape, ensuring reliable and accurate measurements is crucial—enter the OEM pressure sensor. As manufacturers strive for superior quality and efficiency, the need for precise pressure measurement solutions cannot be understated. But what happens when traditional methods fall short? This raises a critical question: How can we ensure the reliability of our pressure sensors to avoid costly production errors?

Traditional Solution Flaws

Many companies still rely on outdated technologies, leading to potential inaccuracies and inefficiencies in their operations. Traditional pressure sensors often suffer from issues like drift over time, environmental sensitivity, and limited calibration options. These limitations can result in erroneous readings—often going unnoticed until they cause significant downtime or product loss. Isn’t it time to rethink these outdated practices?

New Technology Principles

Recent advancements in sensor technology have embraced newer principles like MEMS (Micro-electromechanical Systems) and advanced digital signal processing. These innovations allow for enhanced sensitivity, temperature compensation, and better linearity over an extended range. This means that OEM pressure sensors can now perform efficiently in various challenging conditions, providing real-time data that helps optimize performance across multiple sectors.

Quantified User Benefits

Users of advanced OEM pressure sensors report a multitude of advantages: reduced maintenance costs, improved accuracy, and increased operational uptime. For example, businesses implementing these modern sensors have seen a 20% decrease in production errors and a 30% improvement in overall equipment effectiveness (OEE). These quantifiable benefits underscore why investing in more sophisticated OEM pressure sensors is a step towards operational excellence.

Conclusion: Actionable Evaluation Criteria

When evaluating pressure sensor solutions, always verify these three metrics: ① Measurement range—ensuring compatibility with your application’s demands, ② Calibration frequency—understanding how often recalibration will be needed, and ③ Response time—assessing how quickly the sensor can react to changes in pressure. Improving your pressure measurement system is essential for achieving greater production consistency and quality assurance.

The Role of OEM Pressure Transducers

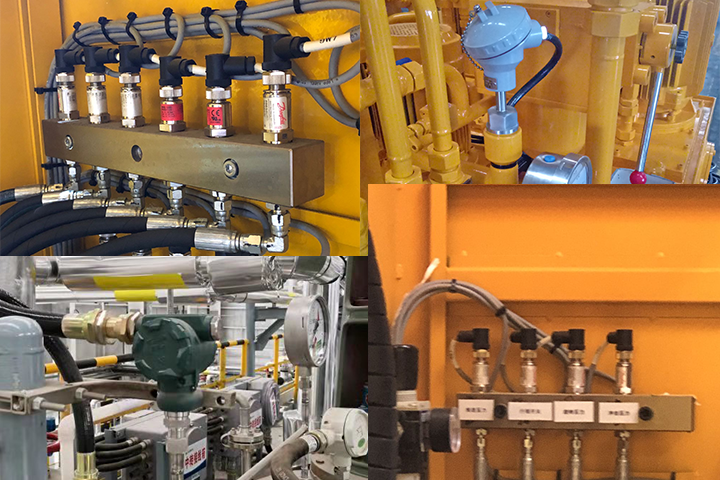

Consider the specific benefits of an oem pressure transducer. These devices provide more precise measurements than their traditional counterparts, enabling tighter control over process parameters. This leads to a more stable production environment, reducing variability and enhancing product integrity. Look, it’s simpler than you think—you just need to choose wisely to reap the benefits of advancements in sensor technology.

Embracing China Pressure Sensors

Furthermore, the rise of the china pressure sensor market has introduced both cost-effective and high-quality alternatives to traditional sensors. Manufacturers from China have leveraged innovative production techniques and automation to create sensors that meet international standards for quality and performance. This opens new avenues for businesses looking for reliable components without breaking the bank. Why not explore these options?

As we’ve seen, evolving from traditional pressure measurement methods to embracing advanced technologies can significantly improve operational efficiency. The extensive benefits of using an OEM pressure sensor, like the ones sourced from CSSPM Sensor, empower industries to enhance productivity, eliminate inaccuracies, and reduce costs. Their commitment to quality and supply chain effectiveness makes them a noteworthy manufacturer in this realm, ensuring all your pressure sensing needs are met with reliability and performance.