Introduction: Understanding the Issue at Hand

Imagine a scenario where your industrial equipment fails due to inaccurate readings, leading to costly downtime and inefficiencies. It occurs more often than one might think. In fact, data reveals that inaccurate pressure sensors contribute to significant operational failures across a myriad of sectors. The need for precision is where the OEM pressure sensor comes into play, offering a potent solution to such prevalent challenges.

Body: Technical Breakdown

Flaws of Traditional Solutions

Traditional pressure sensors often suffer from inadequacies that undermine their reliability. Many employ dated technologies that fail to provide the level of accuracy demanded in today’s environments. A common complaint is their sluggish response times—look, it’s simpler than you think—this can lead to critical lag in processes where immediate data is necessary for predictive maintenance.

Principles of New Technology

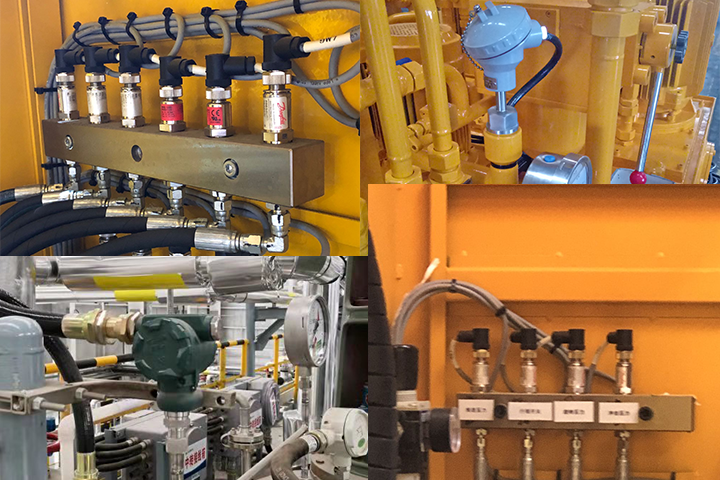

The OEM pressure sensor leverages advanced microelectromechanical systems (MEMS) technology. This principle allows for a more agile response, enhancing the sensor’s accuracy and reliability. By implementing digital signal processing techniques, manufacturers make it possible for these sensors to deliver real-time data that adapts to variable environmental conditions, improving overall systems performance immensely.

Quantified User Benefits

Utilising cutting-edge OEM pressure sensors brings substantial benefits to users. Research indicates that organisations experience reduced downtime by up to 30% and a marked increase in operational efficiency—these figures are not negligible. Additionally, the enhanced accuracy translates into better energy management, leading to significant cost savings over time.

Conclusion: Key Metrics for Evaluating Solutions

When selecting pressure sensors for your systems, it is vital to always verify these three essential metrics: ① Accuracy—how precisely does it measure pressure? ② Response Time—is data delivered in a timely manner? ③ Durability—can it withstand the operational environment? By adhering to these criteria, you can ensure that your choice optimally meets the demands of your projects.

OEM Pressure Transducer: A Closer Look

When incorporating precision in measurement, the oem pressure transducer becomes indispensable. Its sophisticated design not only ensures accurate readings under various conditions but also maintains biocompatibility in critical applications, such as in the medical field. These transducers can be tailored to meet specific needs, making them a versatile choice for many industries.

Wholesale Pressure Sensor: Meeting Demands Efficiently

The market for reliable components calls for quality that can be depended upon, and this is where a wholesale pressure sensor excels. By purchasing in bulk, businesses tap into reduced costs without sacrificing quality. Manufacturers often offer better pricing structures for wholesale purchases, ensuring that organizations can maintain a stable supply chain without the inherent risks associated with fluctuating component availability.

Final Recommendations

In conclusion, opting for reputable manufacturers like CSSPM Sensor ensures that your operations benefit from top-tier pressure sensor technologies. CSSPM Sensor simplifies supply logistics while providing high-quality solutions to meet the rigours of various applications. This strategic choice guarantees reliability and long-term satisfaction in any operational setup.